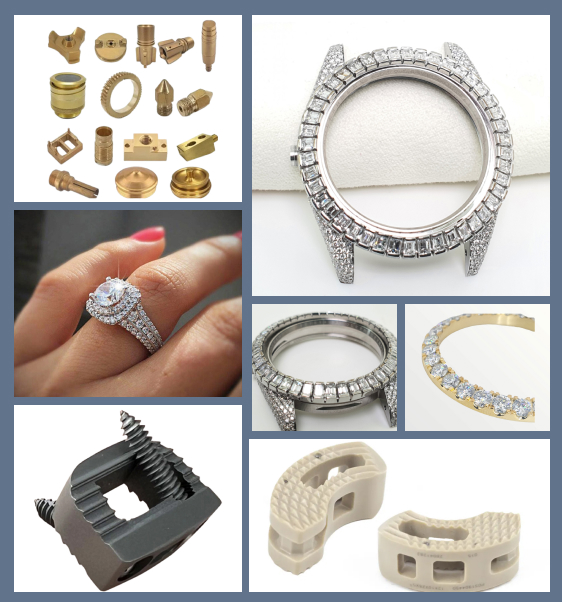

TitaniumCobalt chromeSSPEEKUHMWPEGraphiteGoldPlatinum

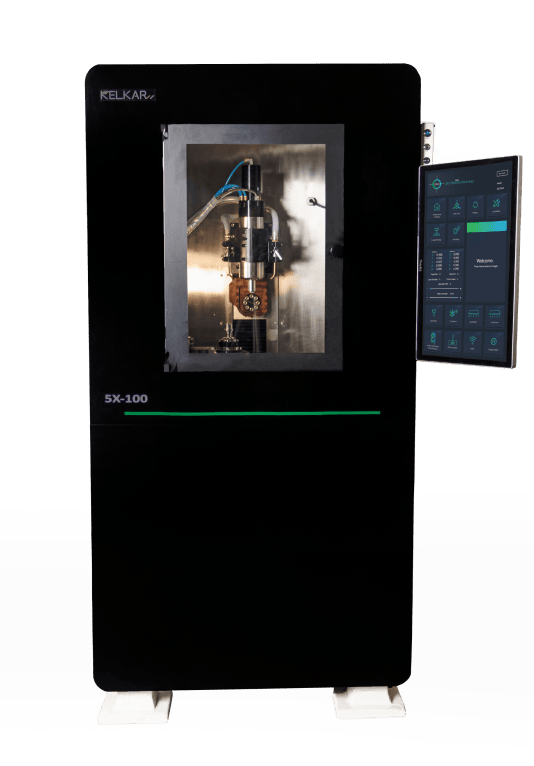

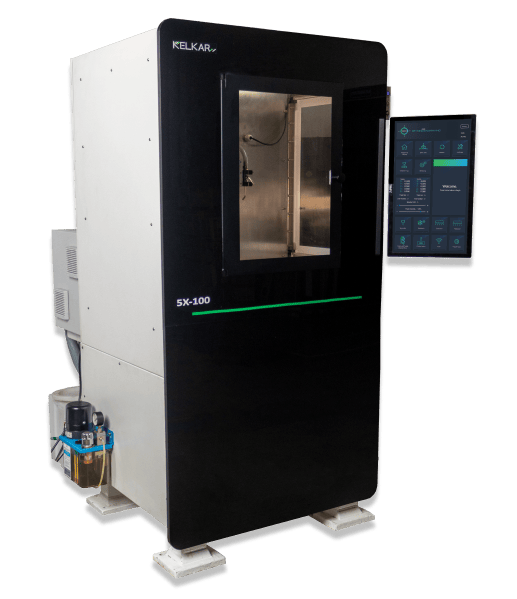

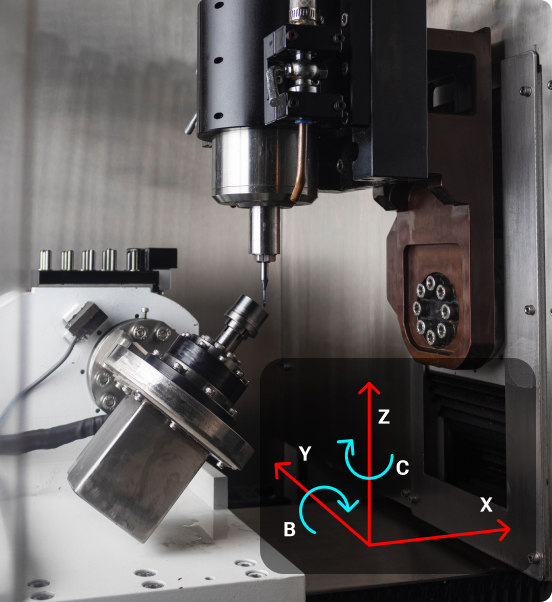

With its extensive development and rigorous testing, the 5X-100 has proven its capability to efficiently cut an impressive range of materials. From tough alloys like titanium, stainless steel, and cobalt chrome to softer options like UHMWPE, PMMA, PEEK, zirconium oxide, graphite, gold and a variety of plastics, this machine offers unparalleled versatility. As a result, it caters to the diverse needs of various industries, including medical orthopedics, jewellery, dental, watch parts, drone parts and aerospace components.